It’s not everyday cross-connection control and backflow makes community news. Recently, The Block Club Chicago indirectly wrote an article on cross-connection control and backflow prevention here which can serve to illustrate some interesting points.

The Block Club’s article is on how small community gardens are folding because Chicago recently changed some rules. The rule changes caused an increase in operational and capital expenditure for these gardens.

Since industrialization, communal gardens subdivided into individual plots have been a popular past time that help reconnect urban dwellers with food sources or escape the city for hobby gardening. In Europe these have been around for centuries. These are called “kolonihaver” in Denmark, “Schrebergarten” in Germany, “Volkstuinen” in the Netherlands, and by other names elsewhere. Some of Chicago’s lower income communities use communal gardens for increased food and nutritional security. In Chicago, the communal gardens also help to maintain city owned land that would otherwise be vacant.

Overview:

Chicago recently updated their cross-connection backflow prevention program requirements mandating reduced pressure zone device instead of the previously required atmospheric vacuum breakers. This change had two distinct consequences. The Block Club article focused on one; the dramatic increase in expenses for community gardens potentially causing several to fold. The second point not emphasized in the article was that this change also protects against backpressure instead of just back-siphonage. The existence of the Block Club’s article seems to point to poor understanding on the part of various stakeholders.

Topical Definitions:

A cross-connection is where the potable water system meets contamination which could affect the quality of the water. Various plumbing codes define cross-connections in different ways but they all generally follow the same pattern. The Uniform Plumbing Code of 2006 defines a cross-connection as:

Any physical connection or arrangement between two otherwise separate piping systems, one of which contains potable water and the other either water of unknown or questionable safety or steam, gas or chemical, whereby there exists the possibility for flow from one system to the other, with the direction offlow depending on the pressure differential between the two systems.

The American Water Works Association (AWWA) acknowledges that a cross-connection can occur between the potable water system and an environment as opposed to a piping system.

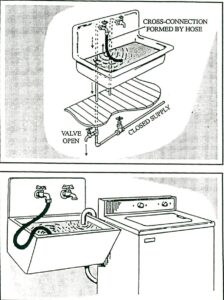

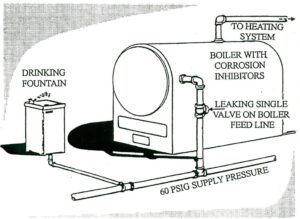

Backflow is essentially the reversal of the hydraulic gradient causing water to flow into the opposite direction. There are two chief kinds of backflow: back siphonage and backpressure. Back siphonage occurs when the potable water system experiences a pressure drop. This causes it to fall below atmospheric pressure and brings water into the system. An example of back siphonage would be a utility/janitor sink that is filled with a non-potable solution and having a main break or similar event compromise system pressure. Back pressure occurs when downstream pressure exceeds supply pressure causing water to reverse flow. Backpressure requires an external force to push back on the water supply as is the case with elevated piping. The American Water Works Association has provided two helpful diagrams to differentiate these two situations:

Backflow Prevention Devices/Assemblies are specifically manufactured plumbing designed to prohibit backflow. The term ‘device’ is typically used for non-testable backflow prevention fittings while ‘assembly’ normally refers to testable fittings. The American Society of Sanitary Engineering, the American Water Works Association, and the University of Southern California’s Foundation for Cross-Connection Control and Hydraulic Research are the main certifying agencies. It is important to note that devices and assemblies must be installed along a specific orientation; some are only allowed to be installed vertically, others only horizontally, and some in various orientations. Incorrect instillation can preclude the proper function of the assembly. There are six basic types of backflow prevention assemblies: air gaps, barometric loops, vacuum breakers (both atmospheric and pressure), double check valve assemblies, double check with intermediate atmospheric vent assemblies, and reduced pressure principle devices. The type of assembly used is based upon the degree of hazard posed by the type of cross-connection. Atmospheric vacuum breakers for instance are only effective against back siphonage and cannot prevent backflow from backpressure.

Legislative Framework:

The Safe Drinking Water Act allows the federal government to grant primacy to local authorities for the administration and enforcement of federal drinking water rules and regulations. Agencies that have primacy must have cross-connection control rules. State requirements for cross connection control programs are highly inconsistent, and state oversight is also varied. States should have a cross connection control program that includes a process for hazard assessment, the selection of appropriate backflow devices, certification and training of backflow device installers, and certification and training of backflow device inspectors.

Discussion and Conclusions:

Recently, Chicago changed requirements for tapping fire hydrants. Previously, atmospheric vacuum breaker devices were required; now reduced pressure zone devices are.

The Block Club article allows some inferences to be made. For instance, the water used in Chicago’s gardens is unmetered and unpaid for through directly tapping fire hydrants. This water would be considered an “apparent loss” as opposed to a “physical loss” on a water audit. The article further goes onto mention that each growing season costs the garden operators about $400. This represents money which could be used to help maintain Chicago’s decaying water infrastructure. Formerly, there was an environmental department in Chicago that helped to offset these costs for low income communities. This department was cut as part of cost conservation measures. This department did not provide some sort of cost accounting metric for Chicago’s Water Utility Board.

It is surprising that Chicago ever allowed atmospheric vacuum breakers to be used for this purpose as areas which could have pesticides or fertilizers applied to it are high risk. This type of situation is one of the most common causes of backflows in the United States. Transient events such as these are notoriously difficult to determine exact societal burdens for. Acute gastrointestinal issues caused by transient events may or may not be widespread enough to be captured. However, even if acutely deleterious health effects are not apparent introduction of organic matter to chlorinated water causes chronically damaging disinfection byproducts and small amounts of pesticides which over time can lead to a dramatic disease burden. It seems that Chicago did not adequately communicate how the backflow device change serves to protect the health of those served by the water system.

However, typical backflow prevention assemblies normally cost around $300-400 for installation and about $60 for annual testing. The cost in Chicago however is $1,700 for installation and $150 for annual testing.

In addition to benefits in the form of food and nutritional security, communal gardens also represent private citizens taking care of public lands without seeking renumeration from the state for their labor or tools. Free maintenance is a clear benefit for Chicago, although without further detailed cost benefit analysis the cost effectiveness of the strategy cannot be determined. However, the roughly $550 per year ($400 in water costs and $150 for annual testing) seems a reasonable amount for the upgrade and maintenance of communal garden-sized city plots.

Overall, the situation is at best a mixed bag. One of the key issues caused by Chicago’s action is that it removed a key source of food and nutrition from low income communities. An issue unresolved by this change is that Chicago’s water utility was not compensated for the water used. An urgent issue fixed through this change was securing the water quality provided by the utility. While greater stakeholder engagement is unlikely to have resolved these issues it could have helped assuage various stakeholder groups or opened a cost benefit dialogue accounting for the free maintenance the city received for the maintenance of these plots.

Further References:

- AWWA Manual 14: Backflow Prevention and Cross Connection Control Recommended Practices Manual

- Journal of Backflow Prevention

- US EPA Cross Connection Control Guidance Manual

- US EPA’s Guidance Manual for Conducting Sanitary Surveys of Public Water Systems (April 1999)

- National Research Council’s 2006 Drinking Water Distribution Systems: Assessing and Reducing Risks or here

- Foundation for Cross-Connection Control and Hydraulic Research a division of University of Southern California

- List of approved backflow assemblies from the University of Southern California (updated annually)

- The most recent 2018 IPC (updated every 3 years)