Per- and polyfluoroalkyl substances (PFAS) are a widely used class of chemicals. You’re probably familiar with some of the popular brand names employing these chemicals such as Teflon, Gortex, and Dockers Stain Defender. As our understanding of PFAS has evolved it is becoming an emergent public health threat. This article is the first in a series serving to provide information on PFAS and it will cover their discovery. Other articles in the series will cover concern, regulation, treatment, environmental fate, contaminated sites, consumer protection, uses and provide sources for further information.

Introduction

Per- and polyfluoroalkyls substances (PFAS) are a family of synthetic substances covering over 4,700 chemicals which have a number of deleterious health effects attributed to them. As of 7 June 2020 California, Connecticut, Colorado, Minnesota, North Carolina, New Hampshire, New Jersey, and Vermont all have state health guidelines for some PFAS. New Jersey’s limits just recently started on 1 June 2020. The US Environmental Protection Agency (EPA) has established a health advisory of 70 parts per trillion of combined PFAS. While PFAS is not directly regulated under the Toxic Substances Control Act (TSCA) it is monitored under the Significant New Use Rule (SNUR). On 20 February 2020 the EPA proposed a supplemental SNUR for PFAS.

Like most things, an exact beginning is hard to quantify. PFAS’ story could start in a letter dated 26 August 1812 when André-Marie Ampère wrote to Humphry Davy postulating the existence of fluorine, or in 1869 when Dmitri Mendelvee positioned fluorine in the periodic table. An equally rational choice would be 1886 when Henri Moissan first isolated elemental fluorine in France leading to his award of the 1906 Nobel Prize in chemistry. Another serious contender would be Thomas Midgley and A. L. Henne’s 1928 invention of Freon and other chlorofluorocarbons (CFCs) in their Fridgidaire laboratory, which at the time was a General Motor’s subsidiary. I am choosing to start PFAS’ story with Roy Plunkett’s 1938 discovery of Teflon and the birth of fluoropolymers.

Discovery

On 6 April 1938 at the Chemours Jackson Laboratory in New Jersey Dr. Roy Plunkett discovered polytetrafluoroethylene (PTFE) by accident while researching new CFC refrigerants. While CFCs are now banned for their deleterious atmospheric effects under the Montreal Protocol, at the time they were used to replace ammonia and sulfur dioxide refrigerants which killed dozens of workers annually. PTFE is better known by its brand name: Teflon. Although CFCs are perfluorinated compounds, PTFE was the first discovered chemical in the class of Per- and polyfluoroalkyl substances.

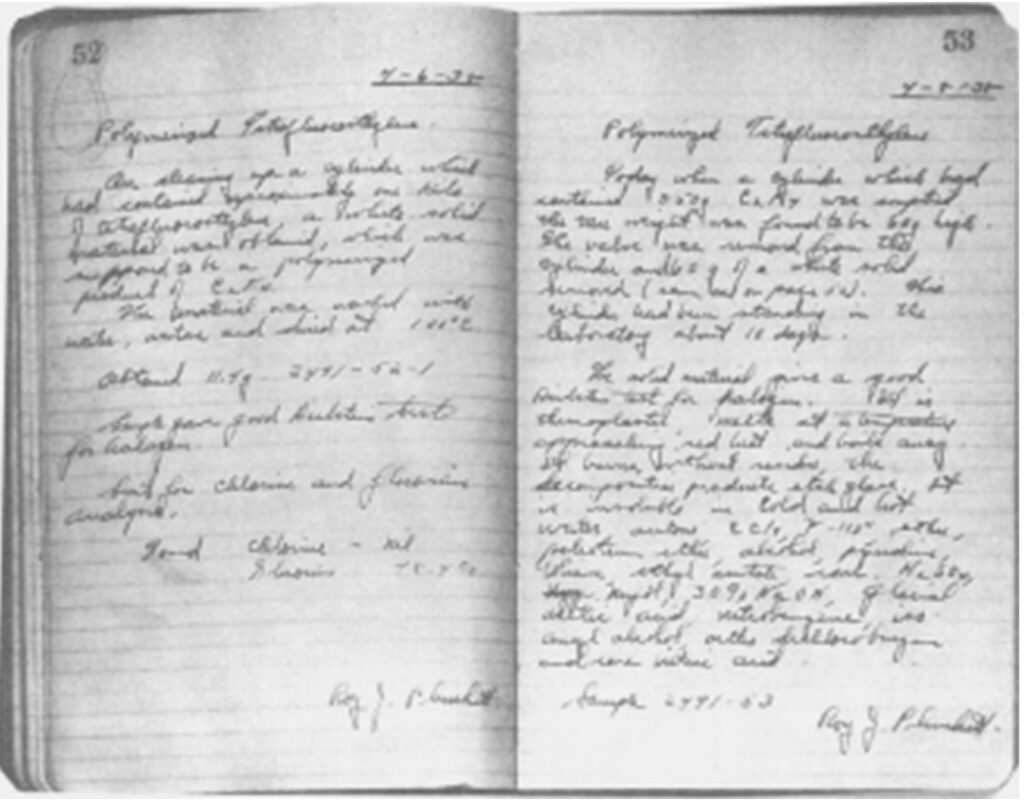

After work on 5 April 1938, Dr. Plunkett and his assistant Jack Rebok reacted tetrafluoroethylene (TFE) with hydrochloric acid then compressed the mixture into metal cylinders and froze it overnight. The next morning on the 6th of April, Jack Rebok placed one of the cylinders onto a balance then opened the stop valve. Only 990 grams of TFE came out of a supposedly 1 kg container. Puzzled by the mass balance, Dr. Plunkett tipped the cylinder over and a white powder fell out. Then Dr. Plunkett stuck a metal wire to try and get more of the substance out. He was unable to get much out that way so eventually Jack Rebok suggested to cut the flask open.

In Dr. Plunkett’s article The History of Polytetrafluoroethylene: Discovery and Development he wrote:

On the morning of April 6, 1938, Jack Rebok, my assistant, selected one of the TFE (tetrafluoroethylene) cylinders that we had been using the previous day and set up the apparatus ready to go. When he opened the valve — to let the TFE gas flow under its own pressure from the cylinder — nothing happened…We were in a quandary. I couldn’t think of anything else to do under the circumstances, so we unscrewed the valve from the cylinder. By this time it was pretty clear that there wasn’t any gas left. I carefully tipped the cylinder upside down, and out came a whitish powder down onto the lab bench. We scraped around some with the wire inside the cylinder…to get some more of the powder. What I got out that way certainly didn’t add up, so I knew there must be more, inside. Finally…we decided to cut open the cylinder. When we did, we found more of the powder packed onto the bottom and lower sides of the cylinder.

Instead of ignoring the powder Dr. Plunkett started experimenting on it and discovered PTFE is highly resistant to corrosive acids, has excellent performance in extreme temperatures, and does not dissolve in solvents. This along with its slippery nature lead to DuPont sending PTFE to its central research department. However, no real commercially viable use was found for PTFE.

Ironically, World War II saved Teflon from oblivion. On its own PTFE, what Dr. Plunkett discovered, is a relatively useless polymer. It melts at around 327°C (≈620°F) and under that temperature sits in a ball of nonflowing gel. PTFE does not dissolve in anything and does not react with acids, bases, or solvents and at the time cost about $100 per pound (about $1,820 per pound or $4.02 per gram in 2020 dollars) to manufacture.

The Manhattan Project was the US effort to develop the atomic bomb and the savior of PTFE. The Manhattan Project needed corrosion resistant materials to separate U-235 from U-238 using differential diffusion of UF6. After Lieutenant General Leslie Groves heard of PTFE’s inertness, he verified it could separate U-235 from U-238. Then following LTG Groves’ request, the US Patent Office placed PTFE under a “Secrecy Order” and it was referred to only as “K-416.” Following military interest, DuPont patented PTFE in 1941 and registered the trade name Teflon in 1944. The secrecy order lasted until 1946; by that time the Manhattan Project had paid for a great deal of research that otherwise would not have been carried out on the polymer and its manufacturing cost dropped tremendously.

Dr. Plunkett is also famous for leading DuPont’s team which added tetraethyllead (CH3CH2)4Pb to gasoline (which was phased out under the Clean Air Act) and for significant improvements to freon (a CFC refrigerant).

Brief PFAS Use Examples

The examples of PFAS extend across all facets of human life, from everyday household cookware to aerospace and electronics. PFAS’ widespread use takes advantage of its beneficial properties: chemical resistance, thermal stability, cryogenic properties, low friction coefficients, low surface energies, low dielectric constants, high volume and surface resistivities, and flame resistance. Once it was used to separate U-235 from U-238, the Manhattan Project immediately started finding other uses for PTFE. For example, PTFE was also used in the Manhattan Project in the antenna cap of proximity fuses thanks to its electrical insulating property and invisibility to Doppler radar. Fuel tank coatings used PTFE because of its resistance to low temperatures. After World War II, Teflon was turned to human well-being and started being used in catheters because of its low friction coefficient. PTFE was also used as insulation for wires and cables. It was even used during the Statue of Liberty’s renovations. PTFE often serves as a precursor for other PFAS chemicals which were ubiquitous until their dangers were realized. PFAS are used in fire fighting foams, ski wax, stain-resistant materials (rugs, clothing, furniture, sprayable stain protectors), cookware, outdoor gear, cosmetics, shaving cream, sunscreen, shampoo, and myriad other applications.

Conclusion

While it may seem easy to villainize Dr. Plunkett for his discovery’s degradation of the environment and damage to human health it is critical to remember Dr. Plunkett in the context of this time. Early refrigerants included sulfur dioxide and ammonia; both regularly poisoned people. His contributions to tetraethyllead boosted octane levels enabling, among other things, advanced plane flight and jets. His work introduced numerous new products and processes which are widely used in medicine, refrigeration, aerosol, electronic, plastics, and aerospace. Several of his innovations are of critical importance to national defense. There was also less awareness of the dangers of persistent chemicals to humans and the environment.

Further References

The EPA has designated Lahne Mattas-Curry as a point of contact and can be reached at mattas-curry.lahne@epa.gov

For more on the history and discovery of PFAS:

- Plunkett R.J. (1986) The History of Polytetrafluoroethylene: Discovery and Development. In: Seymour R.B., Kirshenbaum G.S. (eds) High Performance Polymers: Their Origin and Development. Springer, Dordrecht https://doi.org/10.1007/978-94-011-7073-4_25

- Ebnesajjad, S. (2016). Expanded PTFE applications handbook: Technology, manufacturing and applications. William Andrew. https://doi.org/10.1016/B978-1-4377-7855-7.00007-9

- Ebnesajjad, S. (2013). Introduction to fluoropolymers: materials, technology and applications. William Andrew. https://doi.org/10.1016/B978-1-4557-7442-5.00003-6

- Tressaud, A. (2018). Fluorine: a paradoxical element (Vol. 5). Academic Press. https://doi.org/10.1016/B978-0-12-812990-6.00001-5

- Blair Crawford, C., & Quinn, B. (2017). Microplastic Pollutants [Internet]. 1st izd. https://doi.org/10.1016/B978-0-12-809406-8.00002-5

- Kinnane, A. (2002). DuPont: From the banks of the Brandywine to miracles of science. EI du Pont de Nemours. DOI:10.5860/choice.40-1513

- ScienceHistory.org on Plunkett

Other articles in the series include PFAS Structure

The EPA’s PFAS website is https://www.epa.gov/pfas

PFASproject.com – a group of faculty, post-doctoral scholars, graduate students, and undergraduates affiliated with the Social Science Environmental Health Research Institute at Northeastern University operating on an NSF grant